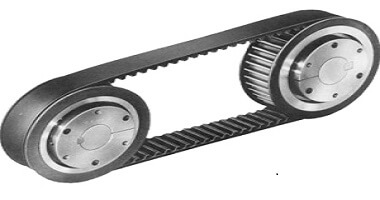

Tire Couplings

Corded tire types

The two significant limitations to the corded tire type coupling are speed and space constraints. As speed increases, the coupling exerts axial forces on the shafts due to the centrifugal forces working on the elastomer. And the geometry of the tire itself makes for a large outside diameter for its torque capability. A design variation includes an inverted tire coupling in which the tire element arcs inward toward the axis, thus overcoming the centrifugal forces at speed. This affords 10-30% higher RPM service, depending on its size.

The corded tire coupling is torsionally soft and can dampen vibration. High radial softness accommodates angular misalignment up to 4° and parallel offset up to 1/8". Rare among elastomeric couplings is its capability to allow a certain amount of axial shaft movement. These properties give corded tire designs a wide variety of applications including those driven by internal combustion engines. This coupling is offered in spacer designs as well as with hubs which can accept bushings.

This design was first marketed in the 1970's and has found success primarily in the process pump industry because of several features that the corded tire lacks. The design utilizes a urethane material that is bonded to two half-circle metal rings, referred to as "shoes", which are then bolted to the two hubs. Torque is transmitted from the hubs through the shoes/bonded joint and then the shear-plane of the split urethane tire.

The design offers advantages such as radial removal of the element halves, high angular misalignment capability (4°), and shock load cushioning. In its standard close coupled configuration, it can span greater BSE lengths than most in-compression couplings, and it also has the large opening in the center of the tire to allow complete flexibility in positioning shaft ends. The outside diameter (OD) of this design is also smaller than the Corded Tire type for similar shaft and torque capacities.

Spacer couplings are achieved by using the same shaft hubs and simply extending the lengths of the steel shoes onto which the elastomer is bonded. Hubs can also be reversed in their mounting orientation to further add to the BSE permutations possible. Bushings are also commonly used on this style of coupling. A heavy duty elastomer option (25% more torque) is available, but it reduces the misalignment capacity by 50%.

And here's a resource for you... it doesn't have to do with just this "Tire Coupling", but instead is a general knowledge base of couplings. It is an internet source sponsored and created by "Lovejoy, Inc.", one of the leading manufacturers of couplings and known for their "Jaw Coupling". Lovejoy became a household name and the coupling of choice a long time ago, and they're still a major force in the industry. Click on this link to be taken to their resource website called... "Coupling Answers.com". It's a great site and you'll learn a lot by spending some time there.

Call us to discuss whether a "Tire Coupling" is the answer to your problem, or to discuss your new application.

Back to Top

Back to Top