Shaft Couplings

Shaft Couplings are critical to the operation of so many industrial and commercial applications.

By definition...A Coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost.

There are basically two types of shaft couplings; Rigid and Flexible. The Rigid couplings are made up of two designs, the Flanged and the Ribbed (or Sleeve). The Flexible is the larger group and contains the Gear, Grid, Disk, Chain, Elastomeric (Tire), and Jaw types, plus hybrids of most of those common types.

Then, of course, there are "sub-categories" of a lot of these couplings, like "Zero-Backlash", which is a special that we've used to couple tach generators to shafts to make certain there is no "slop" in the drive transmission of RPM's when a process is critical and requires exact numbers. And other types like "Fluid Couplings", which act like a mechanical "soft start" to help absorb shock loads. We've applied them to crushers in the past and they're typically used in higher horsepower applications to reduce voltage/current spikes, and/or applications where starting a load "across the line" would be detrimental to the physical health of the driven equipment. But those are specials and if it's something you need, we'll help you out. For our purposes, here however, it's not the focus of our information on this website.

| Rigid Couplings Description: Rigid couplings are usually used when it is critical that the driver and driven shafts must rotate at precisely the same speed and angle of rotation. Click the picture to be taken to the Rigid Coupling page. |

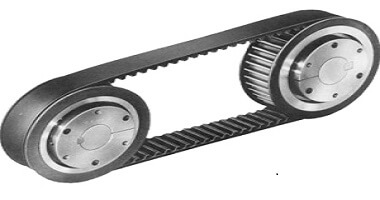

Flexible Couplings Description: Flexible couplings make up the majority of application solutions in the industrial and commercial world. Click the picture to be taken to the Flexible Coupling main page. |

Back to Top

Back to Top