Chains and Sprockets

Chains and sprockets are the equivalents of belts and sheaves except made of metal and having "teeth" to drive them rather than the friction on the sides. A chain and sprocket are used primarily when one needs the driver and driven shafts to turn in true synchronism without worrying about any "slippage".

A chain is an assembly of "links", connected in a long, single, piece. They are usually made of steel but depending on application and environment, may be made of other material such as Nylon or Teflon, used in the food processing industry. There are two types of chains, based on their use and application.

The first type has links that are fabricated of "round bar stock" formed into an "oval" shape ad welded together, which allows the chain to have movement in two directions. This type of chain is commonly used for "lifting" (such as hoists), towing heavy loads, or securing loads on a truck for hauling. It is also the type of chain used on the "anchor" of a ship. If your interested in the details of this type of chain, you can open this link to the specs for "Welded Steel Chain" as published by the NACM (National Association of Chain Manufacturers). This type of chain has been traced back to the Second Century BC.

The second type is the "roller chain", which is what we are going to discuss in our topic. Chains of this type are flexible in only one direction and are designed to intermesh with the teeth of a "sprocket" to transfer power from one shaft to another. Typically, the roller chain used in power transmission operates at "low speeds", i.e. from approximately 30 to 500 FPM (feet per minute) linear speed. There are some "high speed" chains that are used for specific purposes, such as timing chains on automobiles, and high-performance motorcycle drive chains. The roller chain may be configured in "multiple" strands. A roller chain can be purchased in single, double, triple, quadruple, and higher. A single chain has one strand, a double has two strands, a triple has three strands, and so on.

Click the links below to open the associated topic detail page.

And when you're ready, give us a call to discuss your needs. We're here to help!

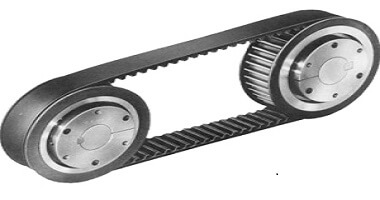

| Roller Chains Description: Roller chain is available in multi-strand designs as well as different materials, depending on the application. Click the picture to be taken to the main Roller Chain page for additional details. |

Sprockets Description: Sprockets are available for a multi-strand chain and in various materials, depending on the application. Click the picture to be taken to the main Sprocket page for additional details. |

Back to Top

Back to Top