Roller Chain

The following description, history, and standards of Roller Chain have been transcribed from Wikipedia.org.

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire and tube drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

Though Hans Renold is credited with inventing the roller chain in 1880, sketches by Leonardo da Vinci in the 16th century show a chain with a roller bearing.

Construction of the chain

There are two types of links; alternating in the bush roller chain. The first type is inner links, having two inner plates held together by two sleeves or bushings upon which rotate two rollers. Inner links alternate with the second type, the outer links, consisting of two outer plates held together by pins passing through the bushings of the inner links. The "bushing less" roller chain is similar in operation though not in construction. Instead of separate bushings or sleeves holding the inner plates together, the plate has a tube stamped into it protruding from the hole which serves the same purpose. This design has the advantage of removing one step in the assembly of the chain.

The roller chain design reduces friction compared to simpler designs, resulting in higher efficiency and less wear. The original selections of the power transmission chain lacked rollers and bushings. Both the inner and outer plates were held by pins that directly contacted the sprocket teeth. However, this configuration exhibited extremely rapid wear of both the sprocket teeth and the inner and outer plates, as they pivoted on the pins. The solution to the problem came with the development of "bushed chains." This chain used pins to hold the outer plates where they passed through the bushings or sleeves, and connected to the inner plates. The new design distributed the wear over a greater area; however, the teeth of the sprockets still wore more rapidly than is desirable, from the sliding friction against the bushings. The addition of rollers surrounding the bushing sleeves of the chain and provided rolling contact with the teeth of the sprockets resulting in excellent resistance to wear of both sprockets and chain as well. There is even very low friction, as long as the chain is sufficiently lubricated. Continuous, clean, lubrication of roller chains is of primary importance for efficient operation as well as correct tensioning.

Lubrication

Many driving chains (for example, in factory equipment, or driving a camshaft inside an internal combustion engine) operate in clean environments, and thus the wearing surfaces (that is, the pins and bushings) are safe from precipitation and airborne grit, many even in a sealed environment such as an oil bath. Some roller chains are designed to have O-rings built into the space between the outside link plate and the inside roller link plates. Chain manufacturers began to include this feature in 1971 after the application was invented by Joseph Montano while working for Whitney Chain of Hartford, Connecticut. O-rings were included as a way to improve lubrication to the links of power transmission chains, a service that is vitally important to extend their working life. These rubber fixtures form a barrier that holds factory applied lubricating grease inside the pin and bushing wear areas. Further, the rubber O-rings prevent dirt and other contaminants from entering inside the chain linkages, where such particles would otherwise cause significant wear.

Many chains have to operate in dirty conditions, and for size or operational reasons cannot be sealed. Examples include chains on farm equipment, bicycles, and chain saws. These chains will necessarily have relatively high rates of wear, particularly when the operators are prepared to accept more friction, less efficiency, more noise, and more frequent replacement as they neglect lubrication and adjustment.

Many oil-based lubricants attract dirt and other particles, eventually forming an abrasive paste that will compound wear on chains. This problem can be circumvented by the use of a "dry" PTFE spray, which forms a solid film after application and repels both particles and moisture.

Variants in design

If the chain is not being used for a high wear application (for instance if it is just transmitting motion from a hand-operated lever to a control shaft on a machine, or a sliding door on an oven), then one of the simpler types of a chain may still be used. Conversely, where extra strength of a smaller pitch is required, the chain might be "siamesed." Instead of just two rows of plates on the outer sides of the chain, there may be three ("duplex"), four ("triplex"), or more rows of plates running parallel. With bushings and rollers between adjacent pairs, and the same number of rows of teeth running in parallel on the sprockets to match, achieving the required strength. Timing chains on automotive engines, for example, typically have multiple rows of plates called strands.

from a hand-operated lever to a control shaft on a machine, or a sliding door on an oven), then one of the simpler types of a chain may still be used. Conversely, where extra strength of a smaller pitch is required, the chain might be "siamesed." Instead of just two rows of plates on the outer sides of the chain, there may be three ("duplex"), four ("triplex"), or more rows of plates running parallel. With bushings and rollers between adjacent pairs, and the same number of rows of teeth running in parallel on the sprockets to match, achieving the required strength. Timing chains on automotive engines, for example, typically have multiple rows of plates called strands.

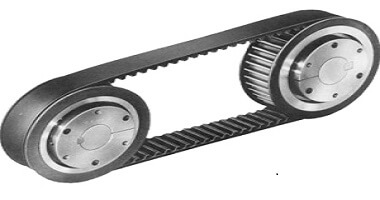

The layout of a roller chain shows in the above picture with the following items identified:

1. Outer plate, 2. Inner plate, 3.

Pin, 4. Bushing, 5. Roller

Roller chain comes in several sizes, the most common American National Standards Institute (ANSI) standards being 40, 50, 60, and 80. The first digit(s) indicate the pitch of the chain in eighths of an inch, with the last digit being 0 for the standard chain, 1 for the lightweight chain, and 5 for a bushed chain with no rollers. Thus, a chain with a half-inch pitch would be a #40 while a #160 sprocket would have teeth spaced 2 inches apart, etc. The metric "pitch," comes in sixteenths of an inch; thus a metric #8 chain (08B-1) would be equivalent to an ANSI #40. Most roller chain is made from plain carbon or alloy steel. Stainless steel, however, is used in food processing machinery or other places where lubrication is a problem, and nylon or brass are occasionally seen for the same reason.

The roller chain is ordinarily connected using a master link (also known as a connecting link). Typically, this is one pin held by a "horseshoe clip" rather than friction fit, allowing it to be inserted or removed with simple tools. A chain with a removable link or pin is also known as a cottered chain, which allows its length to be adjusted. Half links (also known as offsets) are available and are used to increase the length of the chain by a single roller. A riveted roller chain has the master link (also known as a connecting link) "riveted" or mashed on the ends. These pins are made to be durable and are not removable.

Uses

-

Roller chains are used in low- to mid-speed drives at around 600 to 800 feet per minute; however, at higher speeds, around 2,000 to 3,000 feet

per minute, V-belts are normally used due to wear and

noise issues.

- A bicycle chain is a form of roller chain. Bicycle chains may have a master link or may require a chain tool for removal and installation.

- A similar but larger and thus stronger chain is used on most motorcycles although it is sometimes replaced by either a toothed belt or a shaft drive, which offer lower noise level and fewer maintenance requirements.

- The great majority of automobile engines use roller chains to drive the camshaft(s). Very high-performance engines often use gear drive, and starting in the early 1960's toothed belts were used by some manufacturers.

- Chains are also used in forklifts using hydraulic rams as a pulley to raise and lower the carriage; however, these chains are not considered roller chains but are classified as lift or leaf chains.

- Chainsaw cutting chains superficially resemble roller chains but are more closely related to leaf chains. They are driven by projecting drive links which also serve to locate the chain onto the bar.

- Chains are used as "conveyors" with many hybrid attaching methods designed into the chain itself.

- Perhaps an unusual use for a pair of motorcycle chains is in the Harrier Jump Jet, where a chain drive from an air motor is used to rotate the movable engine nozzles, allowing them to be pointed downwards for hovering flight, or to the rear for normal forward flight, a system known as Thrust vectoring.

Chain strength

The most common measure of roller chain's strength is tensile strength. Tensile strength represents how much load a chain can withstand under a one-time load before breaking. Just as important as tensile strength is a chain's fatigue strength. The critical factors in a chain's fatigue strength are the quality of steel used to manufacture the chain, the heat treatment of the chain components, the quality of the pitch hole fabrication of the link plates, and the type of shot plus the intensity of shot peen coverage on the link plates. Other factors can include the thickness of the link plates and the design (contour) of the link plates. The rule of thumb, for roller chain operating on a continuous drive, is to not exceed a mere 1/6 or 1/9 of the chain's tensile strength, depending on the type of master links used (press-fit vs. slip-fit). Roller chains operating on a continuous drive beyond these thresholds can and typically do fail prematurely via link plate fatigue failure.

The standard minimum ultimate strength of the ANSI 29.1 steel chain is 12,500 x (pitch, in inches)2. X-ring and O-ring chains greatly decrease wear by utilizing internal lubricants, increasing chain life. The internal lubrication is inserted employing a vacuum when riveting the chain together.

Chain standards

Standards organizations (such as ANSI and ISO) maintain standards for design, dimensions, and interchangeability of transmission chains.

Tabulated below is a presentation of key dimensions from these standards, expressed in fractions of an inch (which was part of the thinking behind the choice of preferred numbers in the ANSI standard):

| Pitch (inches) | Pitch expressed in eighths |

ANSI standard chain number |

Width (inches) |

|---|---|---|---|

| 1⁄4 | 2⁄8 | 25 | 1⁄8 |

| 3⁄8 | 3⁄8 | 35 | 3⁄16 |

| 1⁄2 | 4⁄8 | 41 | 1⁄4 |

| 1⁄2 | 4⁄8 | 40 | 5⁄16 |

| 5⁄8 | 5⁄8 | 50 | 3⁄8 |

| 3⁄4 | 6⁄8 | 60 | 1⁄2 |

| 1 | 8⁄8 | 80 | 5⁄8 |

|

Notes: |

|||

Applying roller chain is NOT for the faint of heart, and requires some serious thinking about the application, speeds, and a whole lot of other parameters. So make sure you talk to us before you blindly select a roller chain for that next "critical" project.

Back to Top

Back to Top